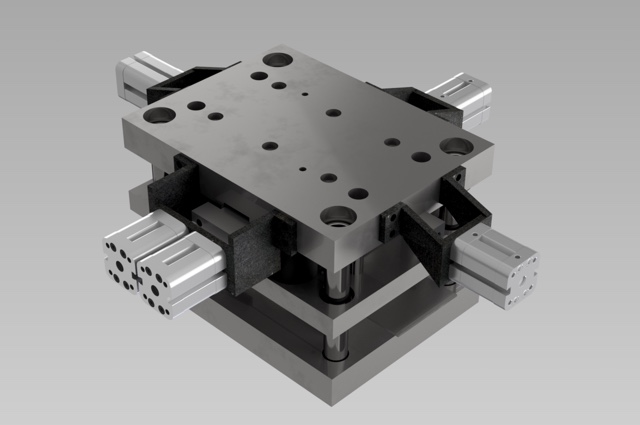

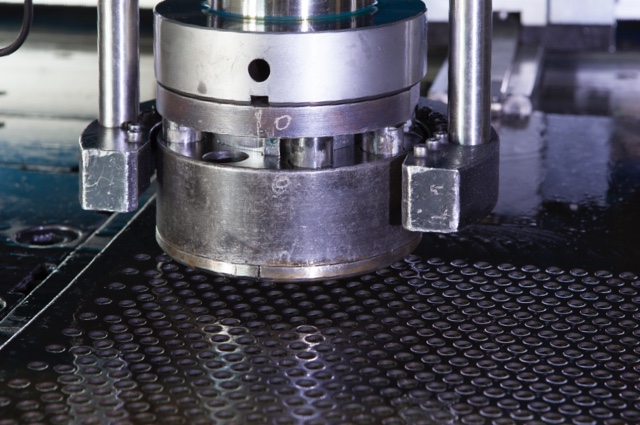

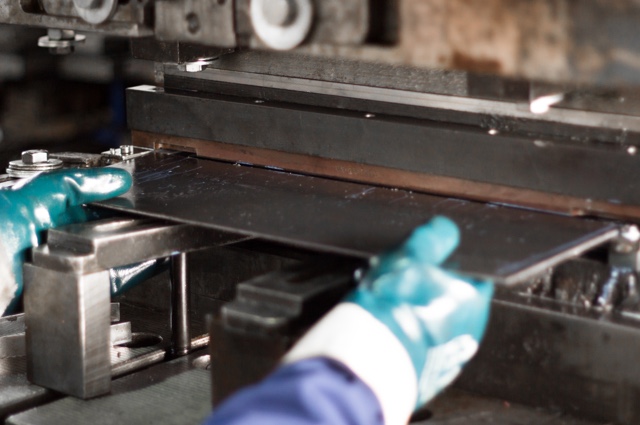

Perfom has modern equipment that allows us a variety of processing of metals and sheets.

Our capacity

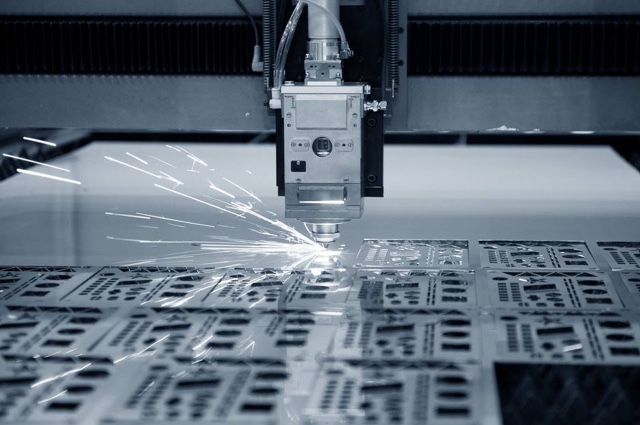

Laser cutting

Laser sheet metal cutting provides enormous opportunities for development engineers to design a wide variety of shapes and use materials that are traditionally considered complex for plastic deformation processing. Making prototypes, small and medium sessions is very simple and fast, there is no need to produce complex tools.