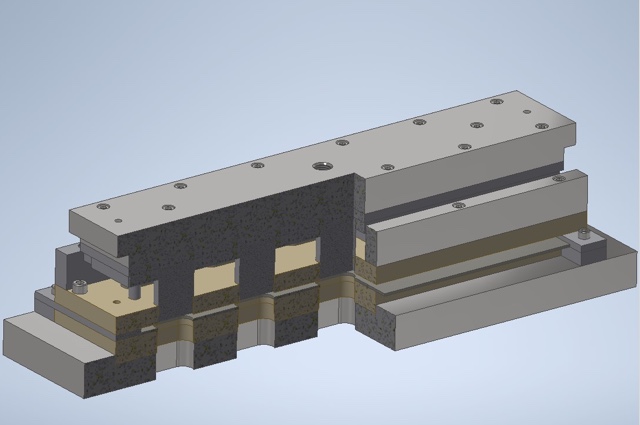

Our capacity includes several thousand tools for perforation and plastic deformation of sheet metal. If we do not have the tools we need, we are able to design and manufacture all the necessary tools in the shortest possible time.

With plastic sheet metal deformation, the tool is the key to the process. We have been building our experience in tool making and sheet metal processing since 1942, today our experienced masters are supported by young engineers.

Except tools for standard perforation, we have significant experience in the design and manufacture of tools for specific and non-standard perforations.

Equipment capacity

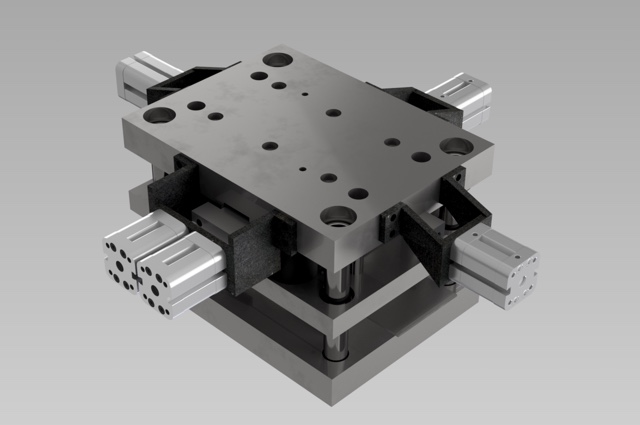

Our manufacturing process begins with tool design using contemporary engineering software.

The entire production process takes place within the company and it is carried out by experienced craftsmen.

If we are not able to design or manufacture tools on our own, we cooperate with specialized and reputable suppliers of tools and services.

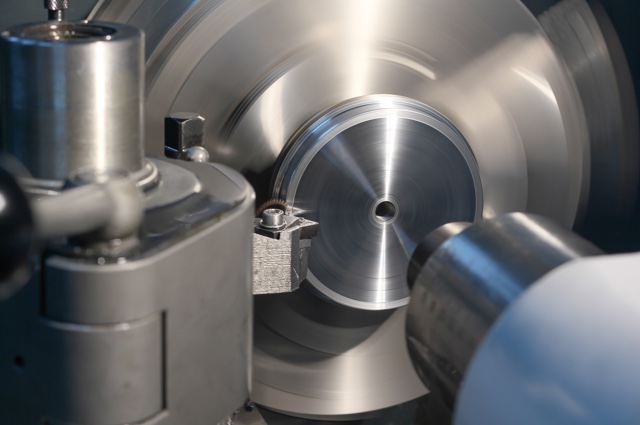

In the production process (especially in perforation) tool parts are worn out. Each tool is monitored in detail during use, all maintenance measures are carried out regularly as well as timely tool replacement.

By regularly maintaining the tools, we ensure an efficient process flow, high product quality and a quick response to a specific customer request.

For key products, we always have more tools available to keep production and delivery running smoothly.

Our capacity includes several thousand tools for perforation and plastic deformation of sheet metal.

If we do not have the tools we need, we are able to design and manufacture all the necessary tools in the shortest possible time.