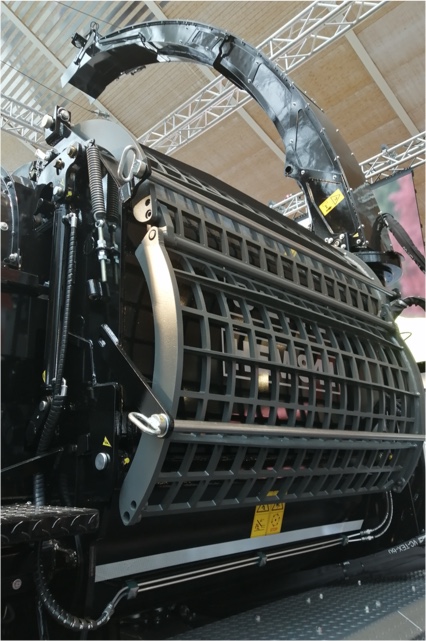

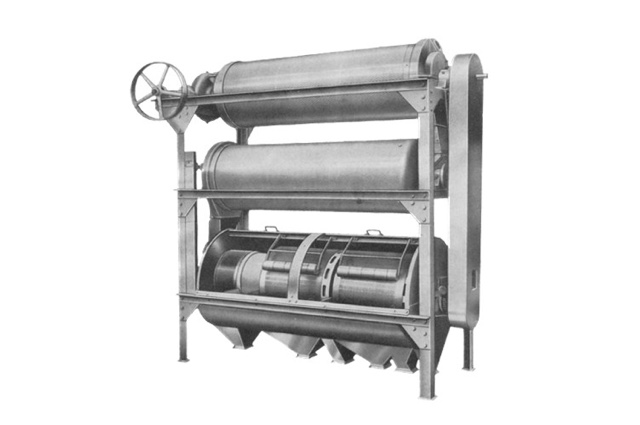

Our products represent a safe link in the production process in mines, quarries, gravel pits, thermal power plants, brick factories, process and recycling industries…

These are important and demanding fields of application, so it is important to have a reliable partner with many years of experience.

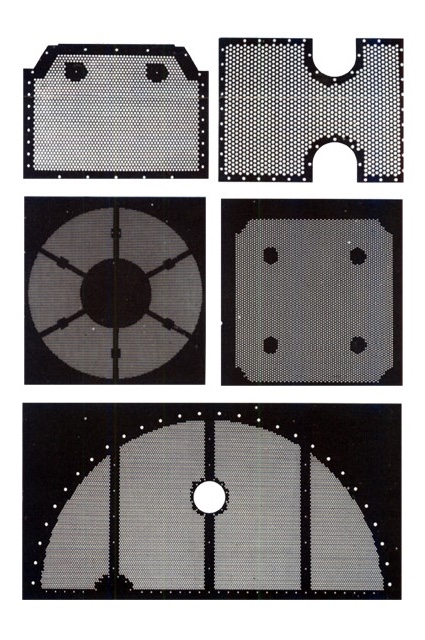

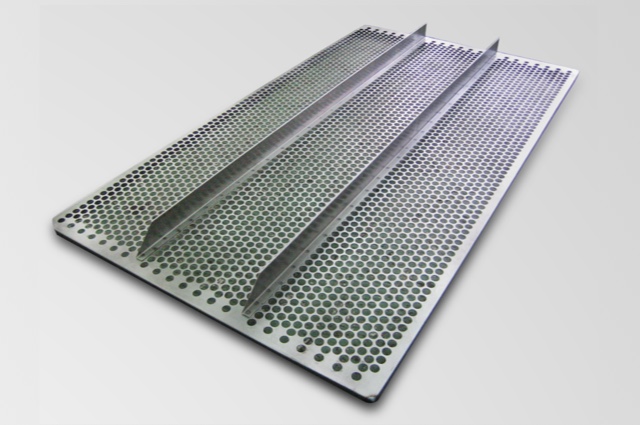

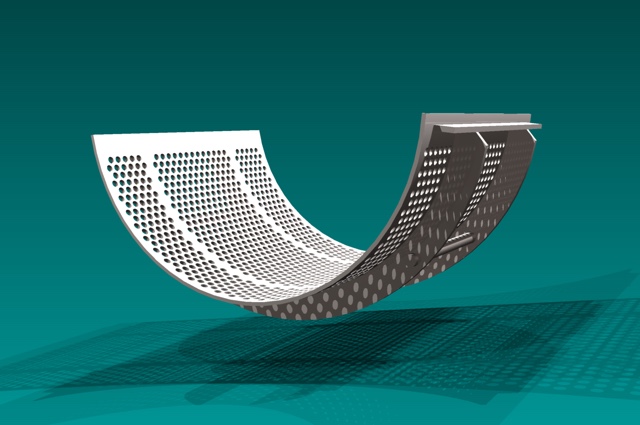

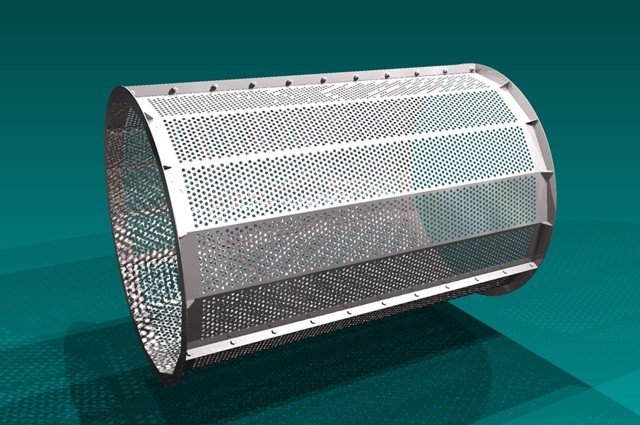

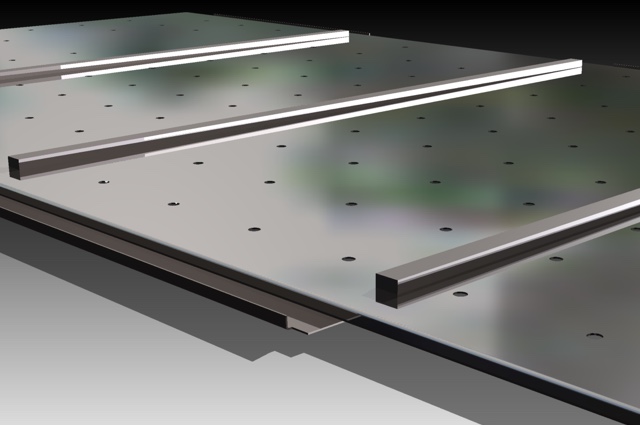

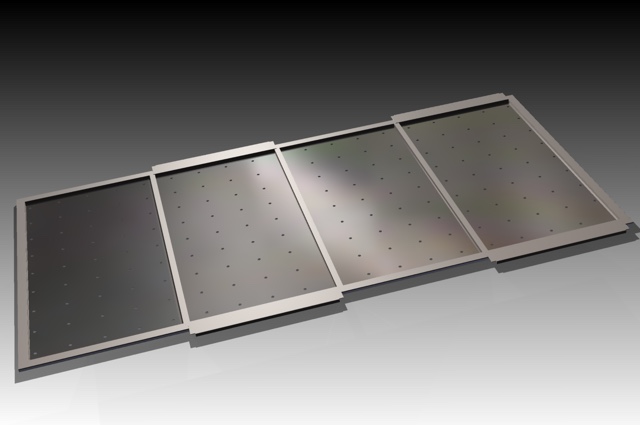

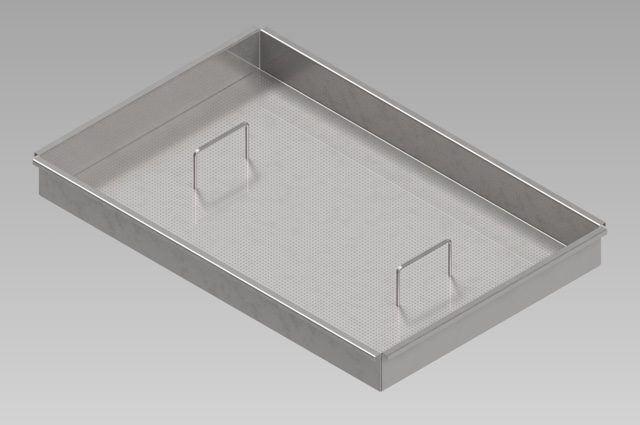

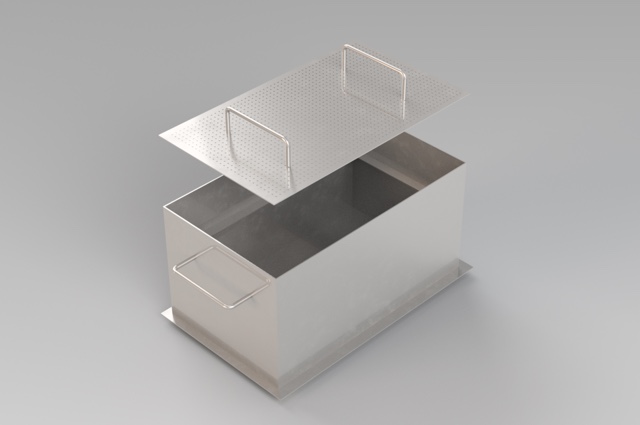

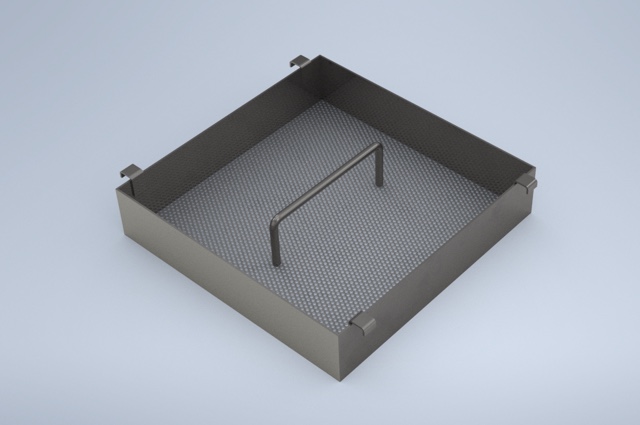

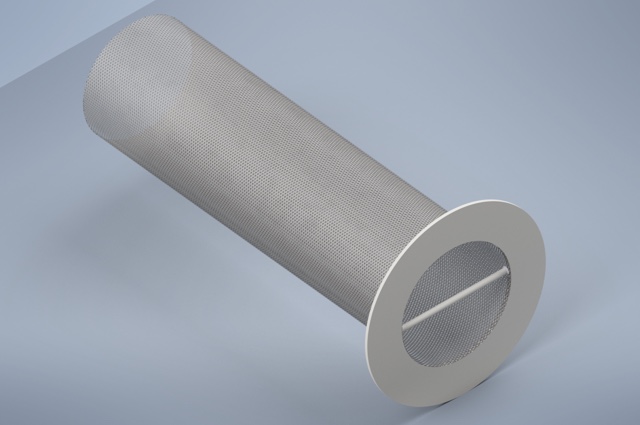

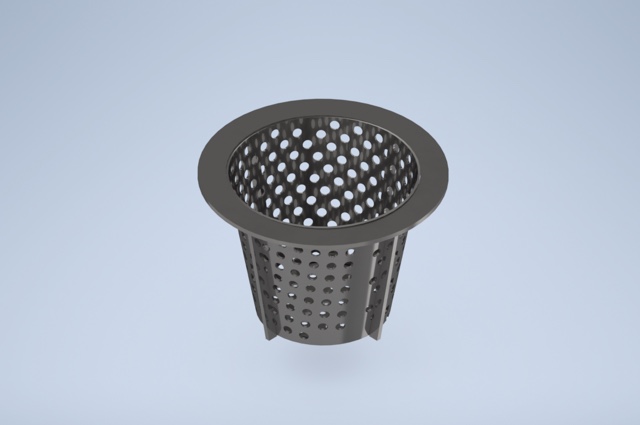

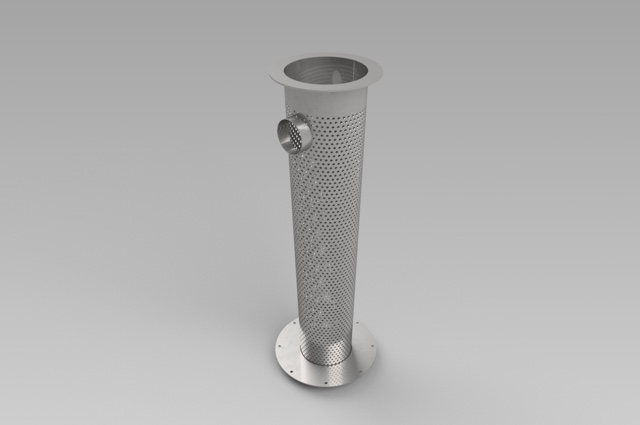

Examples of perforated sieves

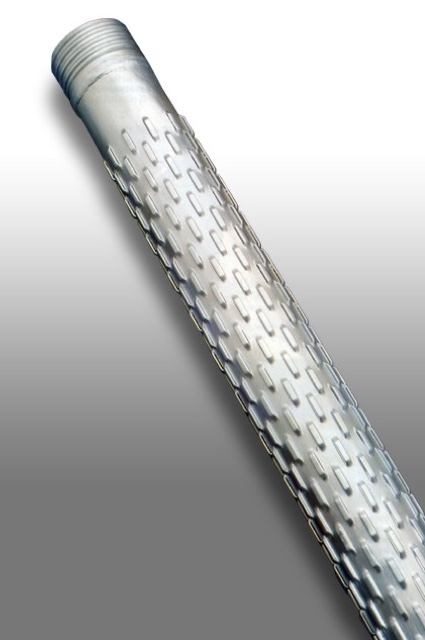

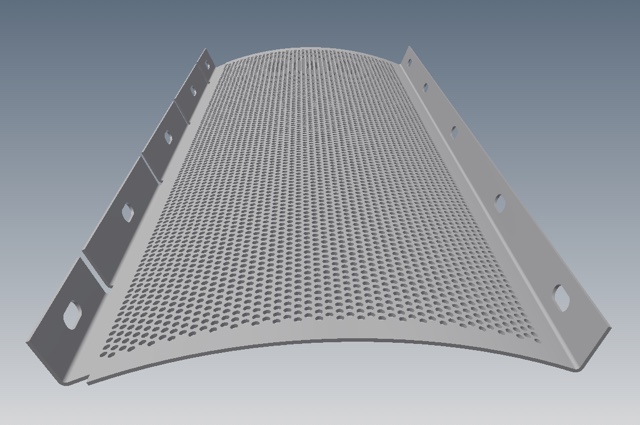

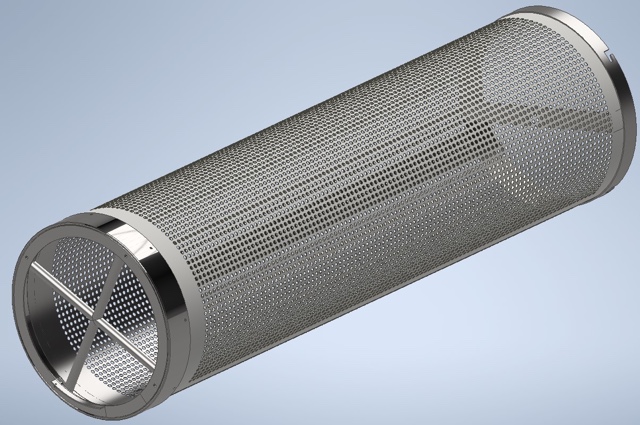

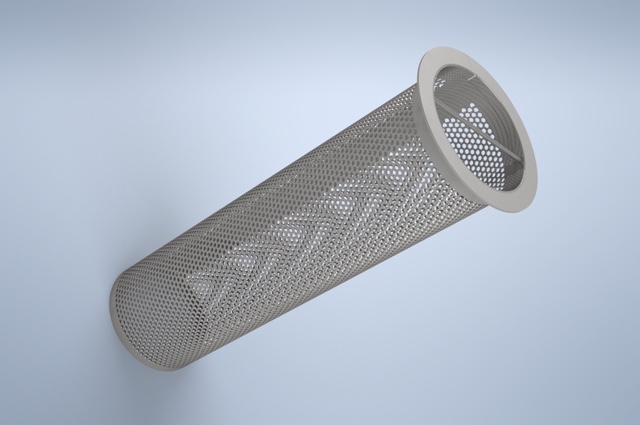

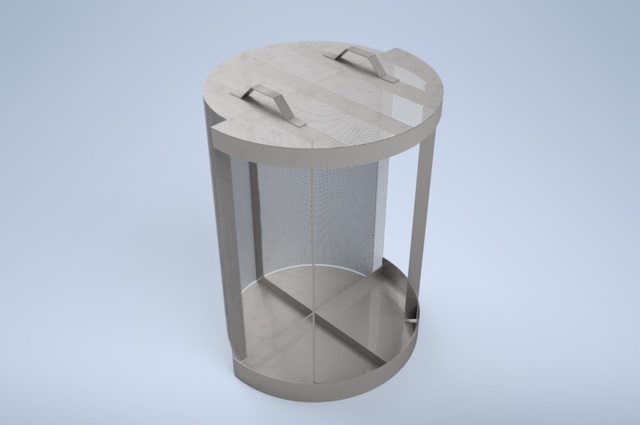

Examples of perforated filters

Characteristics

Material

Thickness

Dimension

Perforations holes

Additional operations

Quantity

Sieves models

Note

Perfom has modern equipment and all the resources necessary for quality production of perforated sieves and filters.

Use our online form to order all our products in a simple and fast way.

Očekujte brz odgovor sa svim neophodnim informacijama vezanim za vašu porudžbinu.