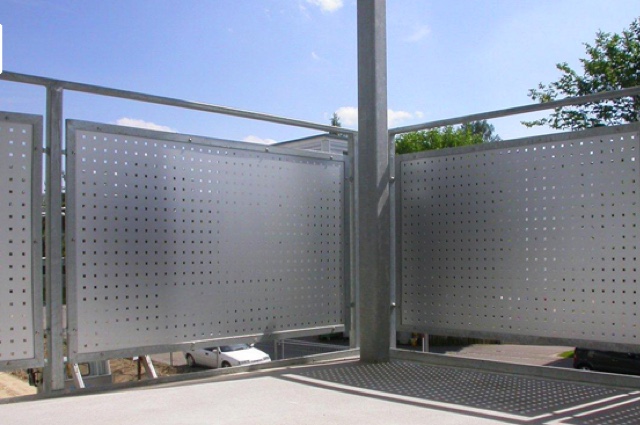

Simply observed, perforated fences are sheet metal panels attached to the construction, but when you decide to apply perforated sheet metal to the fence of your home or business space, you need to change your point of view.

Fences are very visible parts of the building, so their appearance is very important. Safety, duration and a simple fence construction process are also very important.

To clarify and determine what we are making

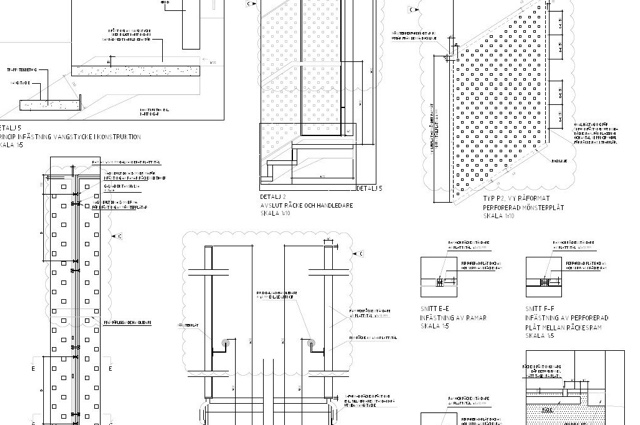

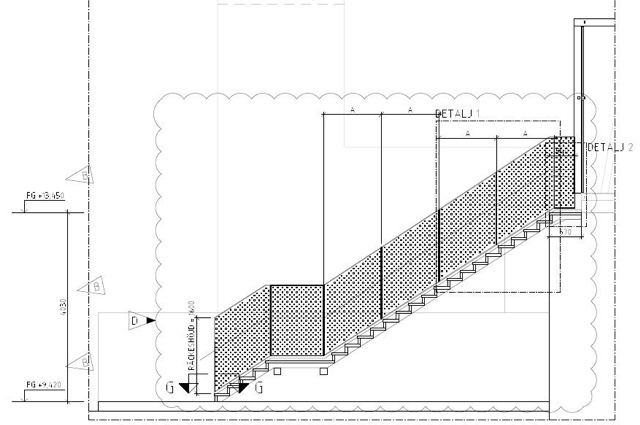

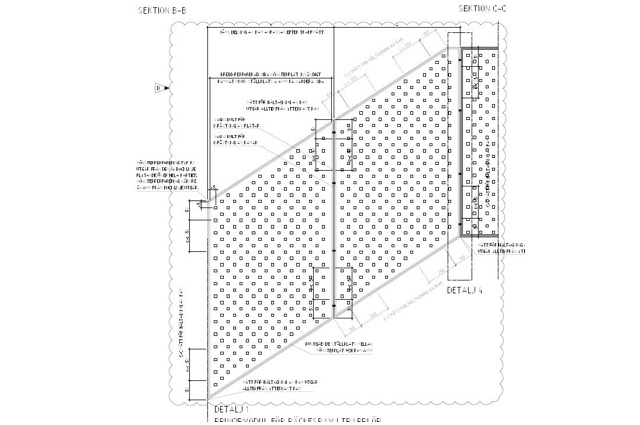

Before the final decision, it is necessary to clarify and harmonize key technical issues related to design and construction.

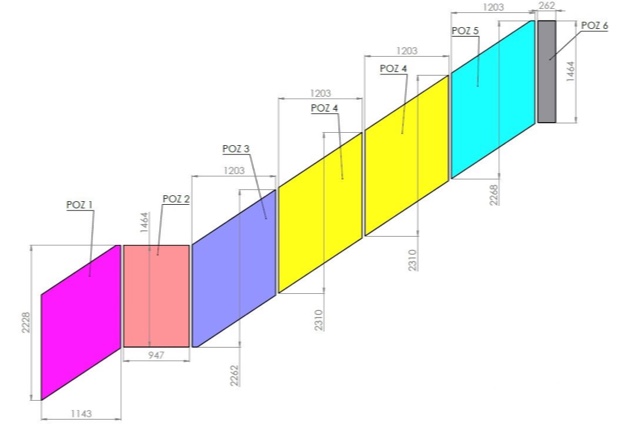

Panel size

Material and surface protection

Aperture production technology – additional operations

Large selection of standard tools and perforated sheets

Panel production on request

Accuracy is important

Perform capacity

Perfom has modern equipment that allows us a variety of processing of metals and sheets.

Process and product development

We have the opportunity to cooperate with all branches of industry and solve various requirements of complex processes.

Safe – long lasting – beautiful

Product development

Application of perforated fences

We offer you the possibility of complete production according to the project requirements… take advantage of the great flexibility of perforated sheet metal and our capacity.

Choose the material, perforation, throughput keeping in mind the requirements of privacy, noise reduction, air flow and light, design and build in harmony with the environment and the requirements of modern architecture.

Use our online form to order all our products in a simple and fast way.

Očekujte brz odgovor sa svim neophodnim informacijama vezanim za vašu porudžbinu.