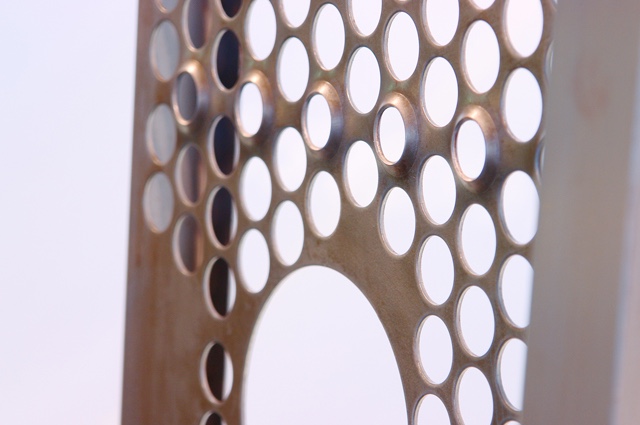

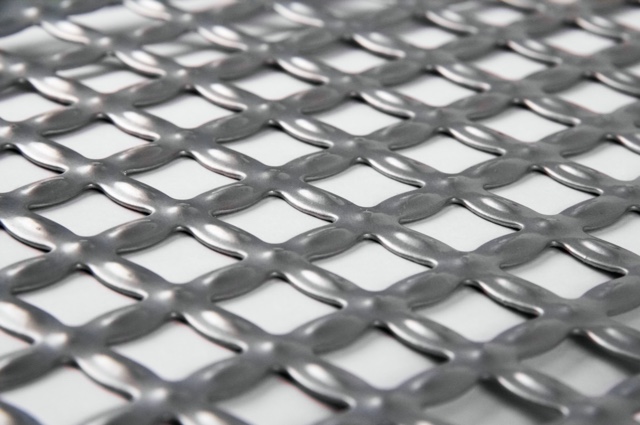

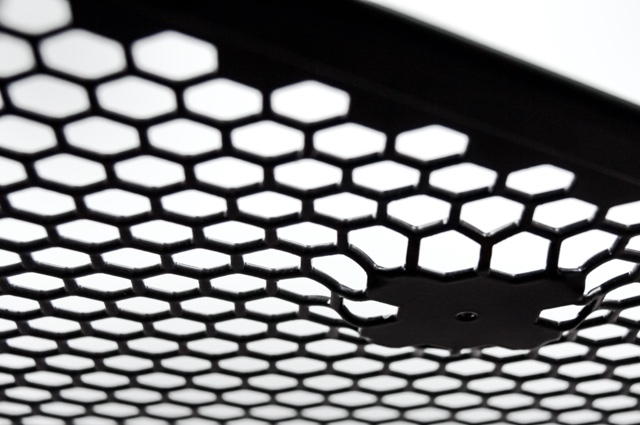

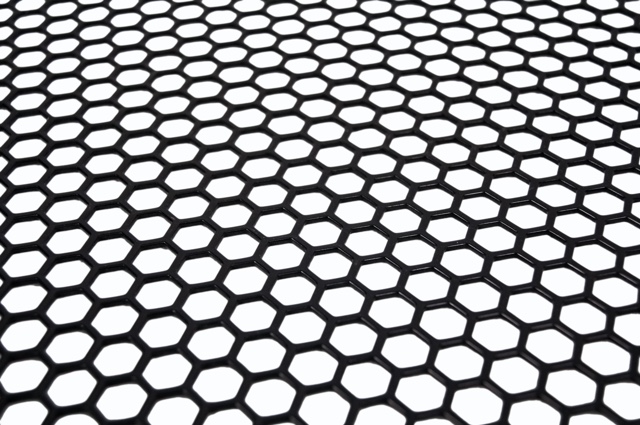

Perforated metal sheet is not just metal with holes. It is a functional, beautiful and inspiring part of our daily lives.

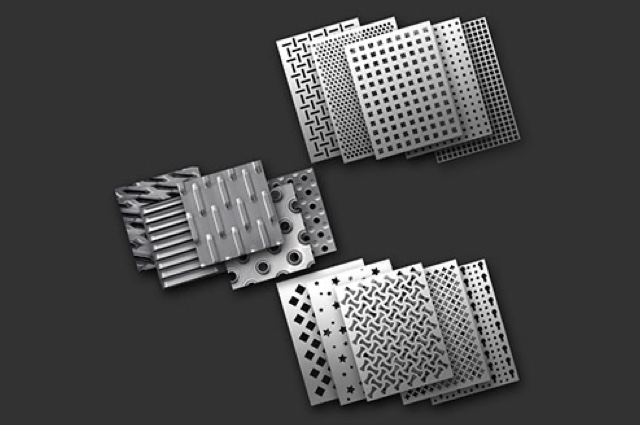

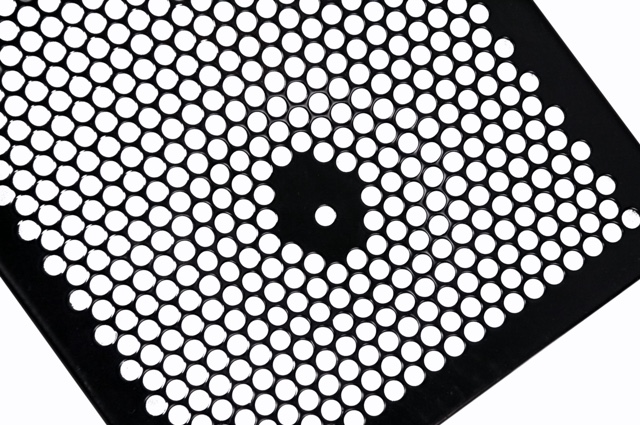

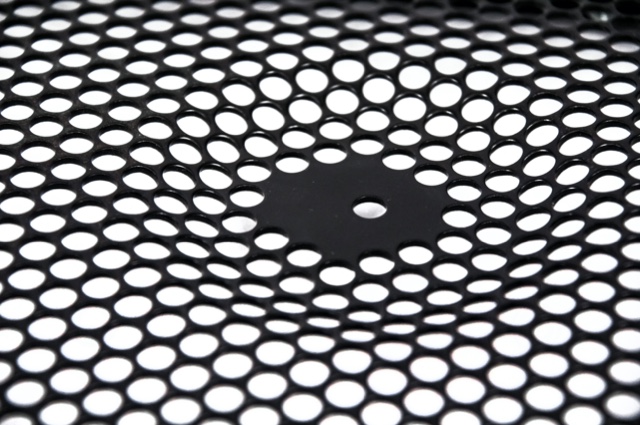

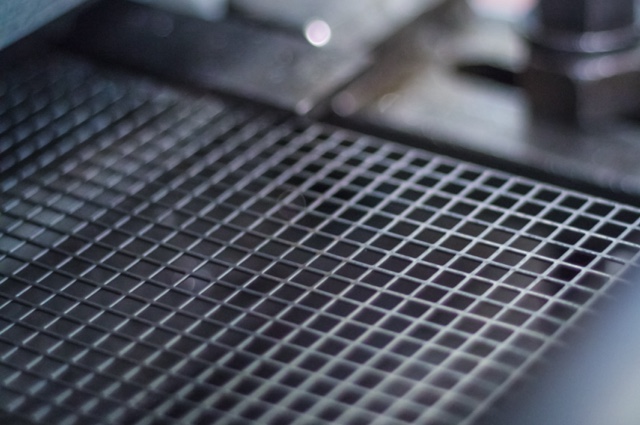

Types of perforation

Examples of perforation

Caracteristics

Material

Thickness

Dimension of sheet

Dimension of strip-coil

Openings of perforations

The hole-thickness ratio *size of the opening – the thickness of the sheet

Open area

Open area is the percentage of open space on a perforated surface without taking into account margins and non-perforated parts.

With standard perforated sheets (except in the case of special orders) the open surface ratio is constant. At smaller sheet thicknesses, it is possible to obtain a high percentage of open surface, at medium and larger thicknesses the throughput decreases.

With the development of special tools, PERFOM is able to offer medium and thick sheets with higher throughput than usual.

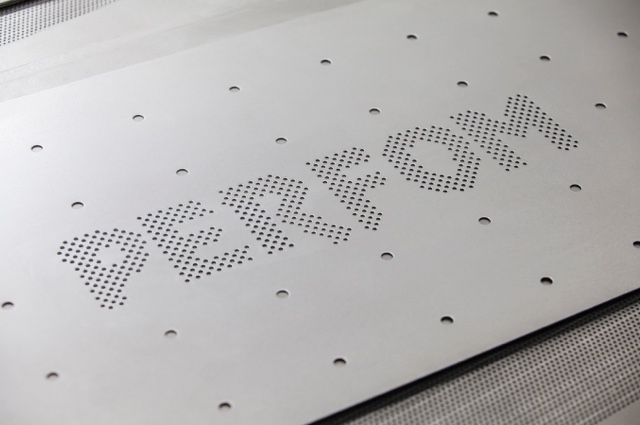

Margins and non-perforated surfaces

A significant advantage of perforated sheets over wire mesh and stretched metal is the ability not to perforate edges, that is margins, as well as other similar non-perforated surfaces, if required.

With the use of modern CNC machines, it is possible to achieve non-perforated surfaces according to the customer’s request, which enables even greater use of perforated sheets.

Beginning and end of the perforation

From the aspect of the beginning and end of perforation, we distinguish two types – complete and incomplete perforation. For technical reasons, the right distance between the perforations is very often formed after the third or fourth line of the opening (incomplete perforation).

If it is important from the aspect of application of the product when ordering, be sure to indicate if a complete start and end of the perforation is necessary.

Flatness

After the perforation process due to great mechanical stress, each board has a certain degree of deformation, which depends on the material, the ratio of the thickness and size of the hole, non-perforated margins…, etc.

After perforation, ironing operation on a roller-straightener is obligatory in order to eliminate deformations.

Production serie size

Additional operations and surface protection

Perfom has modern equipment and all the resources necessary for quality production of perforated sheets.

Standards and tolerances (PDF catalog).

Download PDF catalog with detailed technical information.

Examples of perforation (PDF catalog).

Download PDF catalog with detailed technical information.

Important ordering information.

Your inquiry or order should contain the following information:

1. Required material

2. Length, width and thickness of the sheet

3. Perforation hole

4. Non-perforated margins

5. Essential tolerances

6. Number of pieces

If necessary, specify additional processing operations, surface protection.

Use our online form to order all our products in a simple and fast way.

Očekujte brz odgovor sa svim neophodnim informacijama vezanim za vašu porudžbinu.