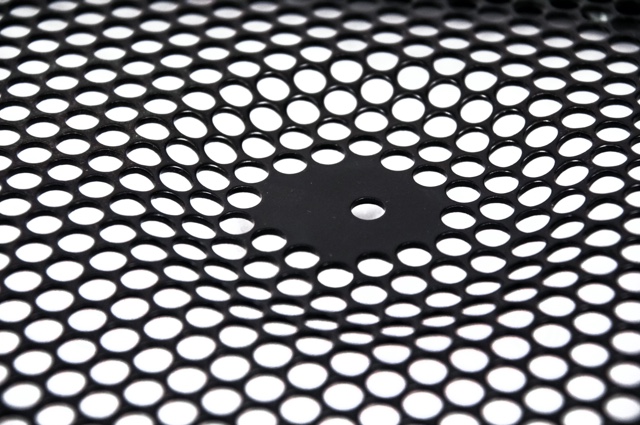

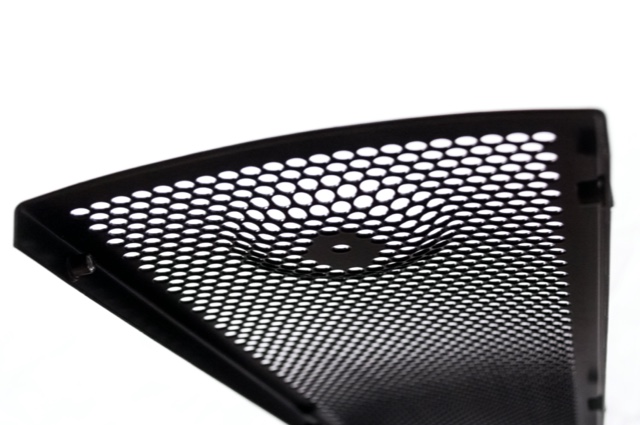

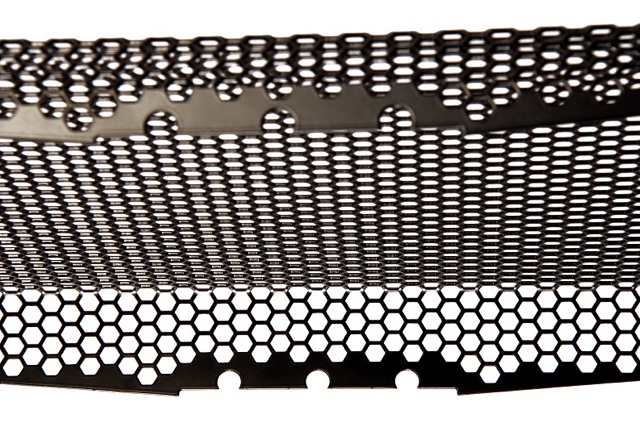

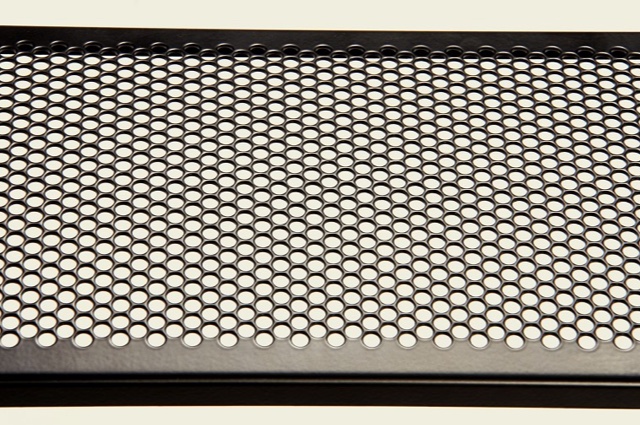

We produce high quality screens and grills, carefully prepared in engineering and design.

The application of perforated screens is very wide, they are used in audio technology (speaker grills), sound insulation, architecture, production facilities to protect employees from dangerous parts of machines, shipbuilding, mechanical engineering, lighting technology…

The possibilities of perforation and laser cutting are almost unlimited, the choice of materials is very large.

You have your design… send an email with a technical drawing or sketch of everything else we do. You are still not sure what kind of screen you want… we are at your disposal in formulating the final design.

Products examples

Read more about the versatility and functionality of perforated sheets.

Read more about the aesthetic value of perforated sheets in architecture.

Technical data

Material

Thickness

Dimensions

Perforation holes

Additional operations

Surface protection

Quantities

Quality

Perfom has modern equipment and all the resources necessary for quality production of perforated screens and grills.

Use our online form to order all our products in a simple and fast way.

Očekujte brz odgovor sa svim neophodnim informacijama vezanim za vašu porudžbinu.