Using CNC perforation technology, it is possible to produce unique perforated panels.

The modern production process enables exceptional precision of production, flexibility and uniqueness of the final product.

Basic technical data of the product

Material

Dimensions

Thickness

Additional operations

Surface protection

Product development

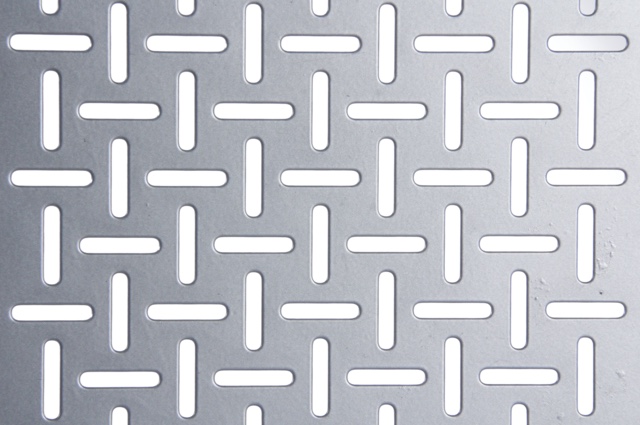

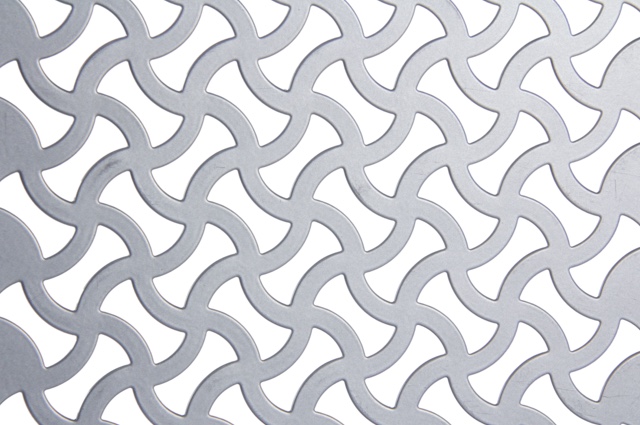

The choice of perforation is extremely large… almost unlimited.

We have three basic groups:

PERFOGRAF (Perforated images/bespoke metal design)

Perforated graphics and photographs. Choose our ready-made solutions or send your request… from graphics, drawings and photos to a unique perforated panel.

PERFORATION ACCORDING TO CUSTOMER REQUEST

You want to use the well-known geometries of squares, circles, rectangles… in the layout according to your idea.

STANDARD PERFORATIONS

Standard openings (square, circle, rectangle, hexagonal, decorative…) in standard layout.

See our suggestions for standard perforations for decorative panels.

Perfom has modern equipment and all the resources necessary for the quality production of perforated panels.

Use our online form to order all our products in a simple and fast way.

Očekujte brz odgovor sa svim neophodnim informacijama vezanim za vašu porudžbinu.